Mother of Pearl

Moderator: Moderator Team

1 post

• Page 1 of 1

Mother of Pearl

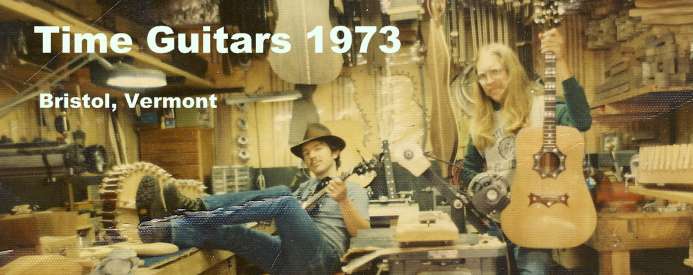

I ran across these Time logos a few days ago. The original pearl inlay logos were made by gluing a small sheet of either mother of pearl or abalone pearl to a thin sheet of wood and pasteing a drawn or photocopied pattern on the face of the pearl. I would cut them out using a Dremel jig saw and then micro files to final shape the edges. the logo would be soaked in acetone to dissolve the glue and free up the pearl, leaving the wood underbase as scrap which I couldn't bear to throw away so I saved most of them. The pearl was then glued to the headstock and outlined using an Exacto knife. More acetone to remove the pearl and then the use of a Dremel Moto Tool with a dentist drill bit to route the cavity for the pearl which was cleaned up with a knife. The pearl was glued into the cavity using a mixture of epoxy and the appropriate wood dust. The work was sanded flat (or curved on fret boards) to reveal the pearl. Of course it was often too much of a bother to wear a dust mask until breathing problems developed but in those days we were all young and impervious to any 'industrial disease'.

-

SollyDad - Worked at Time

- Posts: 10

- Joined: Tue Mar 25, 2008 2:12 pm

1 post

• Page 1 of 1

Who is online

Users browsing this forum: No registered users and 1 guest